Hevea Brasiliensis, Para Rubber

Description

This section is from the book "Rubber And Rubber Planting", by R. H. Lock. Also available from Amazon: Rubber And Rubber Planting.

Hevea Brasiliensis, Para Rubber

About 21 different species of Hevea are found in the Amazon region of North-West Brazil. Of these Hevea brasiliensis is the most important, and furnishes the highest quality of rubber.

Hevea brasiliensis is a tall and handsome tree, often reaching a height of 90 feet, whilst the circumference near the ground may exceed 12 feet Commercially, its most important feature is the bark, which reaches a thickness of an inch or more in well-developed trees.

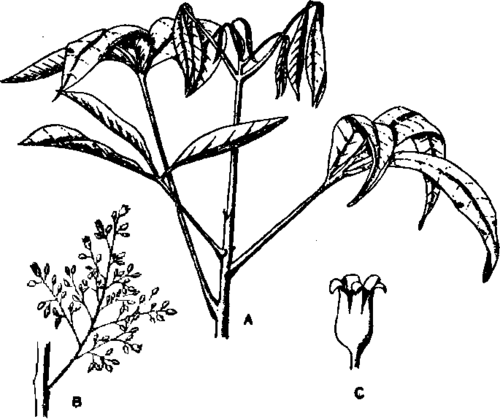

In addition to containing an abundant store of latex, yielding from 30 to 40 per cent, of rubber, the bark of Hevea possesses an admirable consistency for the passage of the various tools used in tapping, combined with a remarkable faculty for recovering from the effect of wounds. The leaves are smooth, with three spear-shaped leaflets, and are very variable in size; indeed, all the characters of the tree are subject to marked variation. In Brazil the shape of the leaves is considered to be a feature by which good and bad varieties can be distinguished. The variety introduced into the East appears to be one of the best, although showing in its turn considerable variation. In Brazil the leaves fall from the trees about June, at the beginning of the so-called dry season, and are replaced by new leaves shortly afterwards. For a few weeks or days, therefore, the trees winter with bare branches.

The trees introduced into Ceylon have encountered there a reversed arrangement of seasons. On the Western side of Ceylon, accordingly, leaf-fall takes place in February.

Fig. 1. Hevea brasiliensis.

A. Young shoot. B. Inflorescence. C Flower.

The flowers appear shortly after the new leaves. They are small and greenish in colour, and possess a pleasant scent comparable with that of the blossom of the lime tree. The male and female flowers are separate, but are grouped in the same panicles. The fruits ripen in about five or six months. Three large seeds, marbled with brown and grey, are contained in a single fruit a hard woody capsule, which bursts open when, ripe and scatters the seeds to a considerable distance.

The structure and physiology of the bark of Hevea will be dealt with in some detail in the following chapters. We may proceed to describe the collection of the rubber in the forests of Brazil.

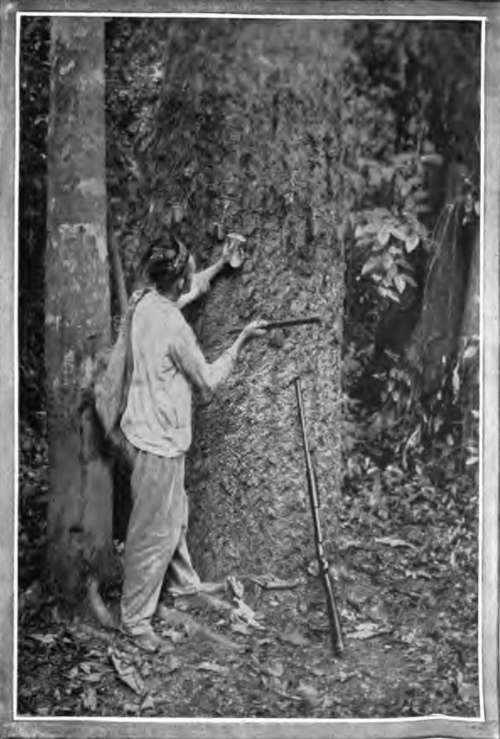

The trees are said to flourish best on rich alluvial clay swamps by the side of rivers. Tapping is carried out between June and February, and is confined to trees of 10 to 15 years of age and upwards. To each seringueiro or collector are assigned from 100 to 150 trees, which are connected by a winding path, or estrade, cut through the undergrowth. Tapping is performed with a hatchet, shaped like a small poleaxe, and the latex is collected in small cups of tinplate, having a sharp edge which can be inserted into the bark. Some days before the tapping proper is begun, the trees are gashed high up with a long-handled hatchet, in order " to make the latex ascend from the roots." The actual tapping is done on alternate days. Beginning at sunrise the seringueiro makes two rounds of his estrade, the first in order to tap the trees and the second in order to collect the latex. The first day's tapping consists of a horizontal row of slanting incisions made with the hatchet as high up as the operator can conveniently reach. On subsequent days fresh rows of cuts are made below the old ones, the bottom of the trunk being reached on the average after about 35 tapping days.

The next operation is smoking, which is carried out as soon as the latex is brought in, before coagulation and putrefaction have time to assert themselves. A smoky fire of wood, mixed with the nuts of certain palms, is made beneath a kind of funnel-shaped chimney. The latex is rotated in the smoke on the surface of a wooden instrument which may be either rod- or paddleshaped. As each successive layer of rubber dries, fresh latex is poured upon the surface until a large block or ball of rubber is formed, which may weigh from 50 to 100 pounds.

Plate II

Tapping Wild Hevea

The method above described appears to be nearly identical with that which has been employed for centuries by the natives of the Amazon valley. The rubber obtained thereby is still adopted as the highest standard of quality in the world's markets.

Continue to:

- prev: List Of The Principal Rubber-Yielding Species

- Table of Contents

- next: Economic Aspects Of The Amazon Rubber Industry