The Glass Blower's Tools

Description

This section is from the book "Glass And Glass Manufacture", by Percival Marson. Also available from Amazon: Glass and Glass Manufacture.

The Glass Blower's Tools

The glass maker's chief tool is the blow-iron. This is a tube of iron J to 1J in. wide and about 4 to 5 ft. long, one end of which is shaped or drawn in so as to be convenient for holding to the lips, and the other end is slightly thickened into a pear-shaped form, on which the hot metal is gathered.

In making crystal tableware the workman manipulates the glass he has gathered on this blow-iron by marveling it on a marver. This is a heavy slab of iron with a polished face about 1 ft. by 1 ft. 6 in., and 1 in. thick, supported on a low table. Sometimes this marver may be a block of wood with hollows of definite forms, in which the workman rotates the hot glass he has gathered to regulate the form and thickness of the metal to suit his work before beginning to blow it out into a hollow bulb.

The pontil is a solid rod of iron of similar length and thickness to the- blow-iron. By gathering a little wad of hot glass on the pontil and sticking it against the end of the bulb attached to the blow-iron, the workman can detach the bulb from the blow-iron and hold it by the pontil to which it has been transferred, and which enables him to work on the other end or opening in the bulb which is exposed in detaching it from the blow-iron.

Glass Worker's Chair

After re-heating the glass, he may shear it with his a issors or shears, open it out with his pucellas, crimple it with his tongs, measure and caliper it, or shape it to a template.

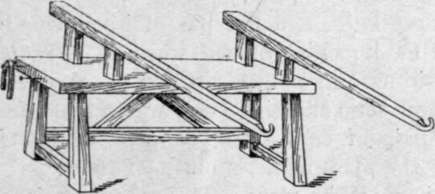

Whilst he is doing such operations he sits in a glass worker's chair. This chair has two long extending arms, which are slightly inclined, and along which he rolls his blow-iron or pontil, with the glass article attached, working upon the rotating form, turning the iron with one hand, whilst he uses his tools with the other hand, to shape or cut the glass to its requisite form whilst it is hot, soft, and malleable.

The shears are like an ordinary pair of scissors, and are used for cutting the hot glass, or shearing off the tops of bowls and wines to their proper height.

The pucellas is a steel, spring-handled tool in the form of tongs, which the workman uses to widen, extend, or reduce the open foims of glass by bringing pressure upon the grips of the tool whilst applying it to the hot glass.

The glass maker also uses another form of spring tool in taking hold of hot glass or pinching hot glass to form. These are the tongs.

The battledore, or pallette, is a flat board of wood with a handle, used for flattening and trueing the bottoms of jugs or decanters, etc.

The chest knife is a flat bar of iron, usually an old file, used for knocking off the waste glass remaining on the blow-irons and pontils after use. A chest or iron box is kept for collecting such waste glass for further use. A pair of compasses, calipers, and a foot rule complete the glass maker's outfit of tools.

Continue to:

- prev: Chapter XI. The Manipulation Of Glass Glass Makers' Tools And Machines

- Table of Contents

- next: Making A Wine-Glass

Tags

glass, manufacturing technology, furnace, glassware, wine glass