Contact Printing

Description

This section is from the book "The Barnet Book Of Photography", by Herts Barnet. Also available from Amazon: The Barnet Book Of Photography.

Contact Printing

The manipulations in the process of contact printing with bromide paper are precisely similar to those given in enlarging, with perhaps a few modifications in exposure and development. There is, however, one great advantageous feature which this developing printing process has over other contact methods, rendering it almost independent of the quality of the negative—that of variation and control of the actinicity of the painting light.

It is well known that in ordinary silver printing a pyro-developed negative generally yields a finer print than one which has been made with a non-staining developer. The reason of this is simply that the slight yellow stain produced by the pyro restrains the power of the blue rays, which is one of the primary colours, and the most active of which white light is composed. It follows, then, that if a negative developed with a non-staining developer be printed behind a pale yellow glass, practically the same effect is produced. Also, and inversely, if we print a pyro-stained negative behind a pale-blue glass we get practically the same conditions. Again, a negative printed from in sunlight will produce a much flatter print than if it had been printed in shade. Now bromide contact printing by daylight is prohibited by the rapidity of the paper, but the above chemical and physical considerations may be applied to artificial light, and practically they are as follows ;—

A dense negative should be printed quickly by a light of high actinicity, and the actinicity may be increased by the interposition of a pale-blue glass.

A thin negative should be printed slowly by a light of low actinicity, and the actinicity may be restrained by the interposition of a pale-yellow glass.

Control over the scale of gradation is obtained by varying the distance between the printing light and the negative.

To carry out the manipulations successfully, method and system are essential.

To this end, the use of a printing board or similar apparatus is advisable.

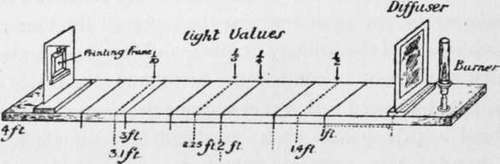

This is simply a graduated board with a burner fixed at one end and a movable support for the printing-frame at the other.

The graduations are made at standard distances, the value of the light at each point being known. These values are calculated from the law of the intensity of light mentioned previously. As an example I have given the values up to one-tenth, and as the scale should not be less than six feet the worker should make it complete up to whatever length he adopts.

Fig. 15. - Printing Boards.

Printing should never be carried out with a naked flame, but a diffuser of tissue paper, ground glass, or opal, should be placed in front of the burner as shown. The scale may, of course, be marked out on a table or similar convenient apparatus, but the burner, or source of illumination, should be a fixed point.

Do not expose at less than a distance of one foot, as even with a diffuser there is a danger of getting uneven lighting. Experiments should be made with a certain negative to ascertain the effect of varying the printing distance and the use of blue and yellow glasses. I believe there is no better printing light than the incandescent mantle, any evil effects due to reduction of intensity from constant use being overcome by a trial exposure, which should be made in any case. This trial exposure is carried out in the manner already described, except that the shield is placed outside the frame, or there is a special printing-frame sold expressly for the purpose.

Development

The same process for development as in enlarging may be employed, but when a large number of prints have to be made a more rapid method is advisable, but an accurate determination of the exposure is very essential. The method consists in using a large volume of developer of normal or nearly normal strength, and adding to it from time to time if necessary. Prints up to whole-plate size should not be previously soaked, but pushed quickly under the developer, the volume being sufficient to allow of this manipulation being carried out successfully. If prints have to be controlled, or developed only to a certain degree, the developer must be sufficiently weak to allow of their being removed to the fixing bath without any possibility of overdevelopment.

Combination printing in contact work is rather more restricted than in enlarging. The manipulations may be carried out in the same way, but with this difference, that the glass side of the negative is made to take the place of the screen. Thus, the second negative is placed in the printing frame with the film side facing the light, and if the "wet print" method be adopted the print is placed in contact with the glass side of the negative.

Where the " way " of the image will allow, the emulsion side of the print is in contact with the glass; if not, then the paper side of the print must be used. This involves slight diffusion and the exposure increased by about six times, but if the negative be varnished this necessity is obviated.

Continue to:

Tags

paper, print, negative, exposure, lens, development, camera, focus