The Sommer Biplane

Description

This section is from the book "The New Art Of Flying", by Waldemar Kaempffert. Also available from Amazon: The New Art of Flying.

The Sommer Biplane

The biplane built by Farman's former pupil Roger Sommer (Fig. 83) follows the Farman type rather closely. The supporting surfaces consist of rubber cloth stretched over wooden ribs. The spread is 33 feet, the depth, 5.2 feet, and the total area 326 feet.

The horizontal rudder is carried well out in front of the machine. It consists of a single horizontal surface. As in the Farman machine, it is controlled by a single lever, which, instead of being placed at the right, is mounted at the left. The operation of this lever and the consequent elevation and depression of the rudder are exactly the same as in the Farman machine.

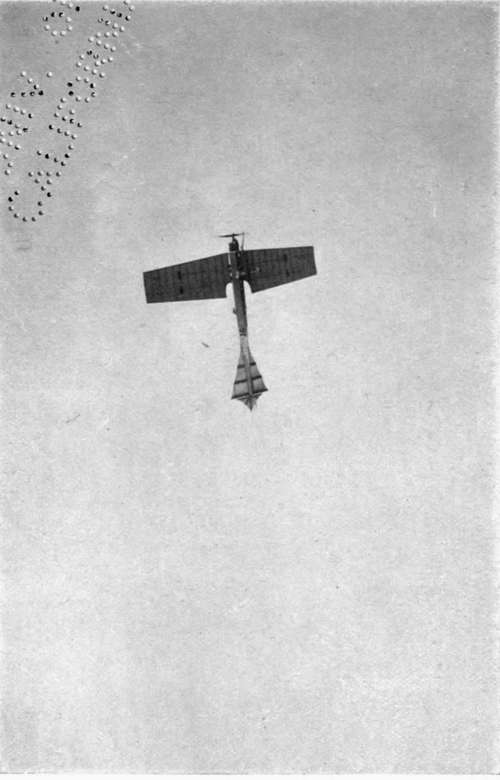

Fig. 83. The 100 horsepower Antoinette monoplane that Hubert Latham flew at Belmont Park during the International Aviation Tournament of 1910.

Photograph by Edwin Levick.

As in the Farman machine, ailerons are employed to maintain side-to-side balance. These ailerons are to be found either on both planes or only on the upper plane. They are not operated, as in the Farman machine, by the lever which controls the horizontal rudder. Instead, the Curtiss principle of using the instinctive movements of the pilot's body is adopted. Wires leading from the ailerons are attached to a yoke partially surrounding the aviator's body. In obedience to the movements of the body the ailerons are pulled down and up respectively.

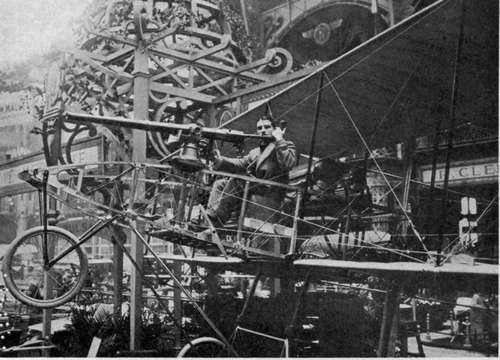

Fig. 78. A Voisin biplane equipped with a Hotchkiss machine gun, exhibited at the 1910 Salon de l'Aéronautique, Paris. This is probably the first attempt to mount a machine gun on an aeroplane.

Photograph by Meurisse.

The vertical rudder is a single surface at the rear of the machine operated, as in the Farman machine, by a foot lever.

To steady the machine a single horizontal surface is mounted in the rear. This surface is movable, not for the purpose of acting as an elevation rudder, but to increase or decrease the stabilising effect. A lever at the aviator's right controls this tail.

The machine is mounted on skids and wheels, the skids serving for alighting. Rubber springs are employed in connection with the wheels, as in the Farman machine.

As a general rule Sommer machines are driven by 50 horse-power Gnome motors, which turn a two-bladed Chauvière propeller at the rate of 1,200 revolutions a minute. Some machines have been fitted with 100 horse-power motors.

Continue to: