Film Developing And Fixing

Description

This section is from the book "Airplane Photography", by Herbert E. Ives. Also available from Amazon: Airplane photography.

Film Developing And Fixing

The problem of quicky handling roll film of large size is one upon whose solution depends in large degree the feasibility of film cameras for aerial work. It presents many difficulties: a long film is unwieldy, is inherently subject to curling, and takes up much space if it is handled entire. For small scale operations roll film can be cut into short strips and developed either by drawing through a tray or, if cost of developer is no object, in a deep tank. In order to make the cutting apart of exposures easy in the dark, film cameras should make some form of punch mark in the film between the exposed parts, or the space between exposures should be uniform, so that a print trimmer set to a definite mark may be used. Racks for holding two or three feet of film, folded back on itself and clasped by spring clothes-pins, are fairly practical. One object of the use of film, however, is to greatly increase the number of possible exposures; and where hundreds instead of dozens of exposures are to be developed, this method takes up entirely too much time.

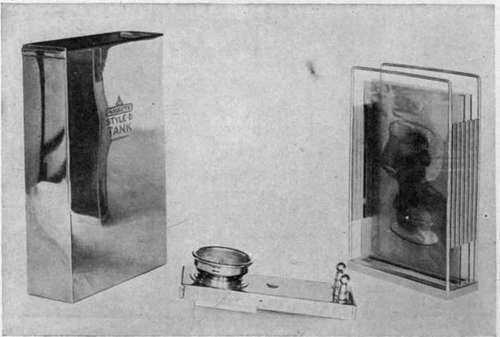

Fig. 116. - Tank and rack for tank development.

Following the practice in moving picture development, film developing machines of various designs have been devised. Among these may be described the G. E. M. machine; the Ansco machine; the Eastman apron machine; the Brock frame and tank apparatus; the Eastman reel machine; and a modification of the latter by the United States Air Service.

The G. E. M. film developing apparatus, similar in idea to the Eastman "apron " method of film developing, as exemplified in the familiar amateur film developing machines, has the film wound in a spiral on a long linked metal frame or chain. After being wound it is placed in a tub of developer, from that to a tub of water, thence to a tub of hypo, and finally to a tub of water, where it is washed in several changes. The objections to the method are that it takes up much floor space for the various tubs, and that it requires such large quantities of solution. To develop a thirty-five foot length of 18 X24 centimeter exposures requires approximately 28 gallons of developer; for the rinsing, 28 gallons of water, and the same for hypo, and at least three times that for washing. In all 168 gallons of water must be brought to the developing hut or lorry.

The Ansco machine makes use of an idea frequently applied in the moving picture industry. The film is carried spirally, upon two cross-arms which bisect each other at right angles, and which contain vertical pins around which the film is looped, beginning at the center and working out.

After it is wound it is placed in a tub of developer, as in the G. E. M. machine. It has an advantage over this apparatus in that the shape of the tubs or tanks is square instead of round. But it is equally extravagant of space and water.

This same criticism may be made of the Eastman apron apparatus for film developing. This is similar to the G. E. M. machine, but differs from it in using a perforated celluloid apron to support the film during the various operations, instead of a metal chain.

The Brock developing outfit consists of a rectangular wooden frame and a three-compartment tank. The frame, which is approximately 3 by 4 feet in size, is used as a support for the 4 inch wide film, which is wound spirally around it, between guiding pins. A special support is provided, on which the frame may be rotated as the film is fed off the camera spool. The frame, with the film on it, is lowered successively into the three narrow but deep compartments of the developing tank. The first compartment holds developer, the next water, the next hypo. The amount of developing solution required is rather large (96 gallons of water in all for a strip of 100 4X5 inch exposures), but because of the small surface exposed to the air, it keeps for a considerable period. The chief demand for floor space with this apparatus is for feeding the film on to the frame.

In the Eastman twin reel machine the film is wound on a wooden drum or reel of large diameter, to form a helix. The drum is suspended so that the bottom edge touches the developing solution, and, upon revolving the drum, every portion of the helix of film is brought into contact with the developer. By shaping the developing tank so that it closely conforms to the shape of the reels, a high economy in quantity of developing agent can be achieved. When developing action is finished, the developer is emptied out, rinse water put in; hypo follows, and then comes the final washing with water. With this apparatus the whole cycle is completed, for the 35 feet length of film above considered, with sevengallonsof water.

The Air Service apparatus differs from the above only in the drying method, which will be described below.

Heavy cut film, such as is marketed under the name of Portrait Film, has not thus far been used in aerial work, except for printing transparencies. It is conceivable, however, that film in the cut form may be used in some future design of camera. This may be developed expeditiously in a tray, six or eight films being handled at a time, in a pile, pulling out the lower one frequently and placing it on top. The core rack system is also available for film in this form, special racks with clips to hold the film being necessary.

Continue to:

Tags

camera, lens, airplane, aerial, film, exposure, photography, maps, birdseye