411. Blanching Celery

Description

This section is from the book "Vegetable Gardening", by Ralph L. Watts. Also available from Amazon: Vegetable Gardening.

411. Blanching Celery

The market in this country demands well-blanched celery, which is secured by requiring the plants to grow when the leaf stalks are in darkness or subdued light. Growth under such conditions destroys the coloring matter of the leaf stems and prevents the formation of additional coloring matter. Any means of protecting the plants from light while they are growing will, therefore, secure light-colored stalks. Blanching also makes the stalks tender and crisp and improves the flavor.

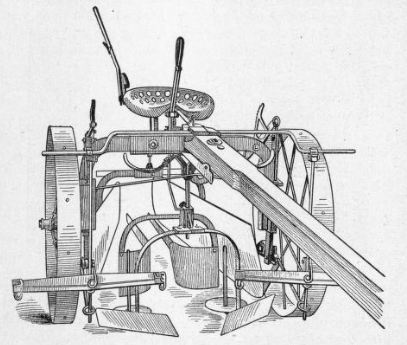

Fig. 77. celery hiller.

For many years, earth has been used most extensively for blanching. When blanched with soil the stalks possess a sweet, nutty flavor that cannot be obtained by any other method. Earth must not be used in warm weather because it causes rust, hence banking does not begin until fall when the weather is cool. When the crop is to be stored in temperatures high enough to encourage some growth, the crop will blanch in storage and will keep better if not blanched at all in the field.

Ridging may begin with the cooler fall weather. Formerly all late celery was first "handled" before the ground was plowed up to the rows. Many growers continue the practice, while others do all of the ridging with special celery hillers. By "handling" is meant the pressing by hand of loose, moist soil about the base of each plant to make the stalks stand erect. Tillage precedes this operation, to provide plenty of fine soil. The hiller (Figure 77) is used immediately after "handling" and subsequently as the plants attain greater height. All of the work of ridging in some of the muck plantations is done with the hiller. Some of the successful growers in muck soils bank, so as to avoid getting much soil next to the bases of the plants, as the latter encourages rust. This is largely a process of shading by banking the earth as high as possible on both sides of the row. Earthing is the most effective means of protecting the crop from severe fall frosts.

The early crop is nearly always blanched by means of boards. It pays to secure sound lumber for this purpose. Hemlock is in common use. "Pecky" cypress is popular for blanching in the Florida fields. The boards should be 12 inches wide, 1 inch thick and 12, 14 or 16 feet long. Ten-inch boards are preferable early in the season before the plants have attained their full size. Half-inch strips nailed across the ends and the middles of the boards will help to prevent warping and splitting.

The early crop should be ready to begin blanching about the middle of July. Boards are placed on edge close to the row on both sides and fastened together with two or three 8-inch double hooks made from heavy galvanized wire. By placing these hooks over the upper edges, the boards may be brought as close together as the tops of the plants will permit. From 10 to 20 days are required for blanching, depending mainly upon weather conditions. In warm, humid weather blanching proceeds much more rapidly than at lower temperatures. A light furrow of soil is often thrown along the lower edges of the boards to exclude the light. The boards are shifted to other rows as the crop is marketed. Thus the same boards may be used half a dozen or more times during the season. Between seasons the lumber should be stored in the dry or stacked in flat piles, as in lumber yards. With good care, sound boards will last at least 15 years. Figure 78 shows a row which was blanched by this method.

Fig. 78. celery blanched with boards.

Paper may also be used in blanching. A machine has been devised which first places a strip of paper against the row and then throws soil against the paper. The individual plants may also be wrapped by hand with brown paper, although this is a tedious operation.

Continue to:

Tags

plants, crops, gardening, cultivated, harvesting, food ,greenhouses, fertiliser, vegitables