177. Forms Of Greenhouses

Description

This section is from the book "Vegetable Gardening", by Ralph L. Watts. Also available from Amazon: Vegetable Gardening.

177. Forms Of Greenhouses

Lean-to, side-hill, even-span and three-quarter span are the distinct forms of greenhouse construction. The lean-to house is the most inexpensive type to construct, and it is often highly satisfactory; but it is most useful when built as a lean-to against a building or wall running southeast and northwest, where there will be practically no shading of the plants. Lean-to houses are sometimes built along the south side of larger greenhouses. While simple in construction, they are not generally popular.

Side-hill greenhouses are of various styles. Sometimes they are built on the ridge and furrow plan with very short slopes to the north. They are inexpensive to construct, but inconvenient to operate, because the ground in the houses usually slopes decidedly—a condition which makes work very tiresome and satisfactory watering difficult.

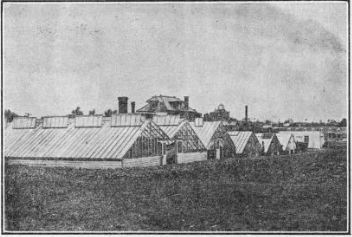

The even-span house (Figure 26) is used extensively. It secures an even distribution of light and gives the plants in all parts of the house the same chance, and for these reasons is the most popular form of construction.

Fig. 26. even-span greenhouses.

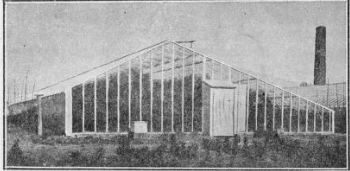

Three-quarter span houses (Figure 27) have been used for many years near Boston. They usually run east and west, and plants grown in them get the full benefit of light and heat from the sun in the forenoon. The houses near Boston are usually 40 feet wide and 200 to 500 feet long.

178. Walls

Whatever material is used in their construction, the walls should be started below frost line.

An excellent plan is to build the concrete walls 2 1/2 feet above grade level and bank them with earth on the outside. Walls made in this way are warm and inexpensive to construct; besides they are much better than those built of wooden posts and boards. Although cedar and locust posts last for many years, the lower boards in a wall will soon decay. If the foundation extends 2 1/2 feet above grade level, there will be a height of 4 feet of glass at the sides between the plate on the concrete wall and the gutter or eaves plate, where sufficient height is desired for a walk next to the wall.

Fig. 27. three-quarter span greenhouse. type used near boston.

179. Roof Construction

The size of the roof bars is determined by the width of the glass and the distances between posts, braces and purlins. The bars should be heavy enough to prevent sagging. Figure 28 shows an approved method of bracing. The pitch of greenhouse roofs varies from 30 to 35 degrees. When the ridge and furrow plan of construction is used, gutters must be provided between the houses. It is important, however, to avoid having gutters if possible, because they decay quickly unless made of metal. Many growers prefer to build with a space of 10 to 15 feet between the houses. This not only renders gutters unnecessary, but avoids shading in the houses and gives room for snow.

180. Glass

It is most economical in the end to use glass of high quality. Single strength was in common use 10 or 15 years ago, but experience has taught greenhouse men that anything inferior to A double strength should not be used. The lighter and inferior grades not only sustain greater breakage from hailstones, but the imperfections may cause injury to the plants by burning.

Fig. 28. A COMMON FORM OF GREENHOUSE BRACING.

Small glass was used extensively in the construction of the old-style houses, which necessitated placing the sash bars close together. This condition increased the cost of construction and decreased the amount of light that could enter. For many years 10 x 12-inch glass was a very common size, but 16 x 24 is the standard size today, and is used to a much greater extent than any other size. It is generally laid with the sash bars 16 inches apart, while 24 inches between roof bars is not uncommon. Many greenhouse managers object to the bars being so far apart on account of the difficulty in making close fits between the laps. If the panes are graded before glazing so that lights of about equal curvature are placed together, there will be very little space between the laps. Twenty inches between sash bars is regarded as the proper distance by some growers, in which case 20 x 24-inch glass is used.

181. Glazing And Painting

A priming coat of paint should be applied to all wood parts before the work of construction is started. The glass is then laid in putty consisting of one part of white lead to five parts of putty. After filling the shoulders of the sash bars the glass is placed with the curve up, and pressed down firmly, squeezing out the surplus putty. This method of glazing is much better than to use putty on the glass, because the putty remains in place and keeps out water and cold air and prevents the escape of heat from the house. When large glass is used, glazing points should be inserted, not only at, but midway between, the laps. After the glass has been laid the house should receive two additional coats of paint and then be painted every year to insure maximum durability.

Continue to:

- prev: 175. Materials Used In Construction Of Greenhouses

- Table of Contents

- next: 182. Ventilators In Greenhouses

Tags

plants, crops, gardening, cultivated, harvesting, food ,greenhouses, fertiliser, vegitables