Chapter XXIV. Printing And Enlarging. Contact Printing

Description

This section is from the book "Airplane Photography", by Herbert E. Ives. Also available from Amazon: Airplane photography.

Chapter XXIV. Printing And Enlarging. Contact Printing

Single prints are made most simply in a printing frame held at a short distance from a light source. When any quantity must be made, as in turning out prints at high speed for distribution to an army before an attack, printing machines are employed. These consist essentially of a light box, a printing frame of plate glass, and a pressure pad. In the commercial models, such as the Crown and the Ansco, which are equipped with electric light, merely bringing the pressure pad down and clamping it automatically turns on the light, while release of pressure terminates the exposure.

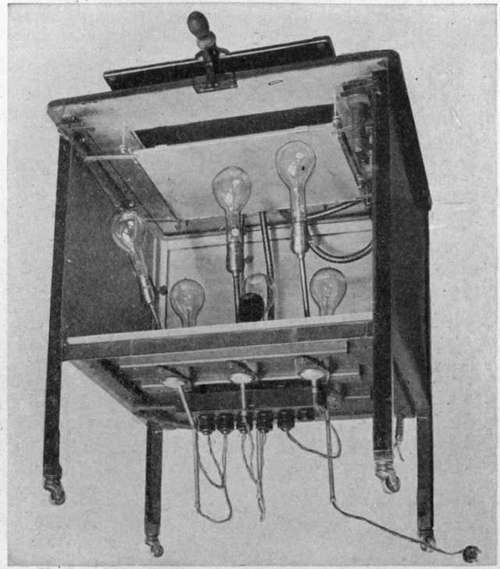

The question of regulating the distribution of light is of considerable importance with negatives taken by focal-plane shutters of non-uniform rate of travel. In the Mclntire printer (Fig. 119), the separate electric bulbs are on long necks in ball and socket joints, so that they can be brought individually closer to the printing surface or farther away from it, thus permitting a wide range of "dodging." This printer also has an automatic time control for the light, a valuable device where many prints from the same negative are desired.

These machines are well suited for printing aerial negatives, either plate or cut film, if used where a source of electric current is available. The chief defect, which may be caused by faulty construction, is imperfect contact between paper and negative, a cause of serious unsharpness on prints destined for minute study in interpretation.

The printing of aerial negatives may be done either on roll or cut paper, and if films are used, a further alternative is offered of handling it either in the roll or in cut form. Where many prints are to be made from one negative roll paper has some advantages, particularly if a developing and drying machine is available. But for moderate numbers the advantage is small, since cut prints can be developed quite conveniently in goodly numbers in the ordinary trays. But the advantages of keeping film in the roll form are very great, both in respect to storage and in respect to handling during printing, as the rollers provide the necessary tension and prevent the film "getting away".

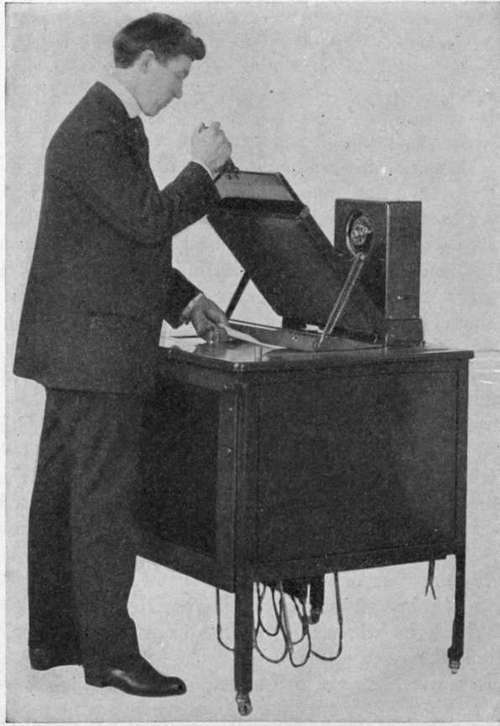

Fig. 118. - Printing machine.

Fig. 119. - Interior of Mclntire printer, showing lamps adjustable in position for "dodging".

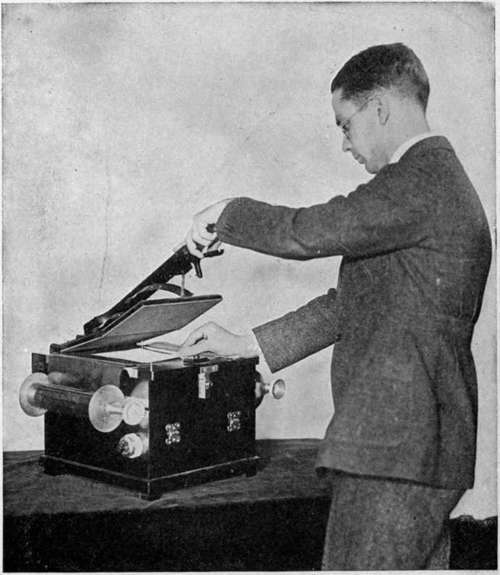

For the American Air Service, cut paper has been used exclusively. For film printing, the Ansco machine has been equipped with roll pivots to take film 24 centimeters wide which may be advanced in either direction by turning large milled heads (Fig. 120). If we put rollers on the two remaining sides of the box to handle paper we transform the printer into the same form as a French machine, in which paper and film are moved at right angles to each other. A disadvantage of this modification, however, is the difficulty of examining the negative to be printed.

Fig. 120. - Film printing machine.

Continue to:

Tags

camera, lens, airplane, aerial, film, exposure, photography, maps, birdseye